INTRODUCTION

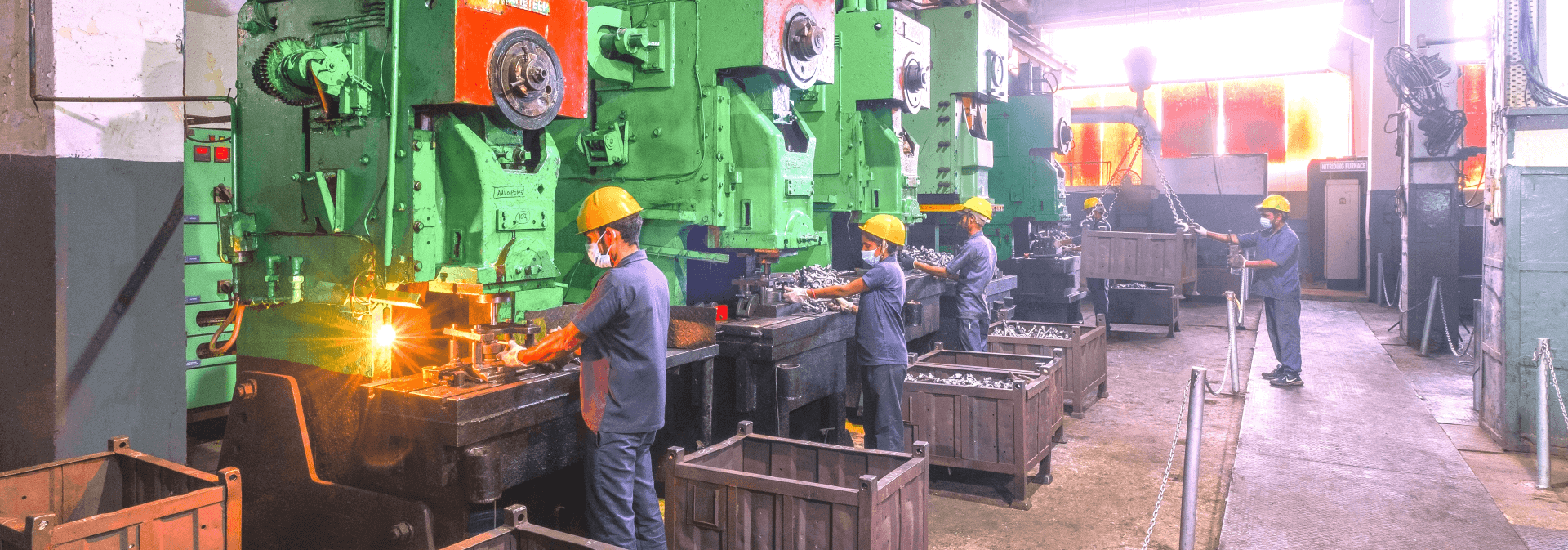

Our Forging Division consists of manufacturing plants in Gurugram, Bhopal & Hosur that manufacture a wide array of forged components like bridge fork bottoms, knuckles, hubs, spindles, transmission parts (gears), engine parts (connecting rods, two-wheeler crankshafts), and engine & transmission components. We manufacture parts of all types of steel including carbon, alloy, and micro alloy steels.

We have latest 2D & 3D design software with Simulation Modelling to enable the product design is done as per customer specifications. Dedicated Modern machine shops with latest CNC machining facility including VMC, turning machine. We have Special Die welding Technology from USA.

Capabilities

| Press Range | No. of Presses | Shot Blasting / Peening |

| 600T - 1350T | 06 NOS | 02 NOS |

Heat Treatment

- Continuous type LPG fixed Quench & Temper Furnaces

- Continous type LPG fired Isothermal Annealing Furnaces

- Continuous type Electricity Heated Mesh Belt Normalising Furnace

- Nitriding Furnace

Quality Inspection & Testing

- Spectrometer (German - Spectro)

- Microscope (Japanese - Olympus)

- Micro Vicker Hardness Tester (Mitutoyo)

- Digital & Optical Hardness Testers

- UTM

- Tensometer

- Ultrasonic Tester

- Eddy Current Sorter

| Press Range | No. of Presses | Shot Blasting / Peening |

| 600T - 1300T | 14 NOS | 07 NOS |

Heat Treatment

- Continuous type LPG fixed Quench & Temper Furnaces

- Continous type LPG fired Isothermal Annealing Furnaces

- Continuous type Electricity Heated Mesh Belt Normalising Furnace

Quality Inspection & Testing

- Spectrometer (German - Spectro)

- Microscope (Japanese - Olympus)

- Micro Vicker Hardness Tester (Mitutoyo)

- Digital & Optical Hardness Testers

- UTM

- Tensometer

- Ultrasonic Tester

- Eddy Current Sorter

| Press Range | No. of Presses | Shot Blasting / Peening |

| 730T - 1350T | 10 NOS (3 screw) | 07 NOS |

Heat Treatment

- Continuous type LPG fixed Quench & Temper Furnaces

- Continous type LPG fired Isothermal Annealing Furnaces

- Continuous type Electricity Heated Mesh Belt Normalising Furnace

Quality Inspection & Testing

- Spectrometer (German - Spectro)

- Microscope (Japanese - Olympus)

- Micro Vicker Hardness Tester (Mitutoyo)

- Digital & Optical Hardness Testers

- UTM

- Tensometer

- Ultrasonic Tester

- Eddy Current Sorter